MEIKE ZHENCHUANG

COMMITTED TO PROVIDING INTELLIGENT MANUFACTURING SOLUTIONS FOR NEW ENERGY

——SUPPORTING THE RISE OF HUMAN INDUSTRY——

TECHNOLOGY COMES FIRSTGOODNESS IS SUPREME, AND BEAUTY IS SUPREME

Meike Zhenchuang's business scope covers solid-state battery production line planning, equipment supply, lithium battery production line planning, equipment supply, sodium battery production line planning, equipment supply, raw material supply, battery laboratory planning, and equipment supply. It is a leading new energy intelligent manufacturing solution service provider in China. |

Product Solution

New Energy Intelligent Manufacturing Solution

Product Solution

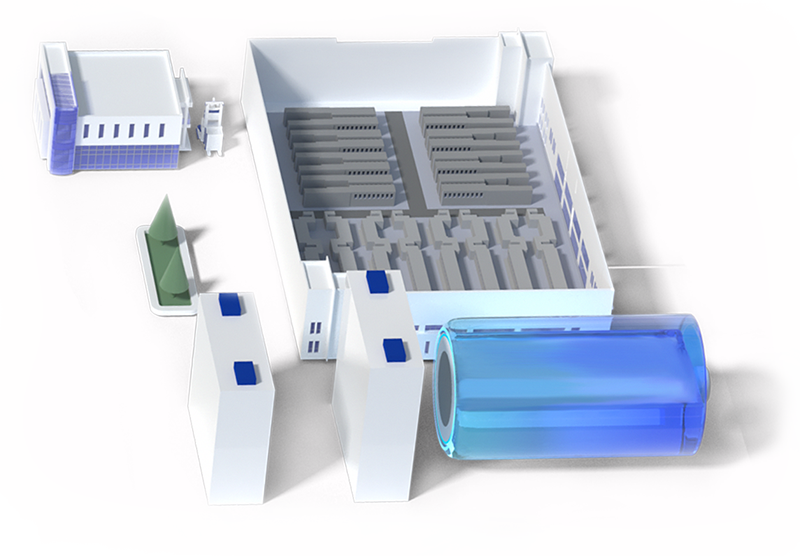

New Energy Intelligent Manufacturing SolutionMeike Zhenchuang is committed to providing intelligent manufacturing solutions for new energy. Our business scope covers solid-state battery production line planning, equipment supply, lithium battery production line planning, equipment supply, sodium battery production line planning, equipment supply, raw material supply, battery laboratory planning, and equipment supply. We are a leading provider of new energy intelligent manufacturing solutions in China. Our products are exported to various parts of the world. Our company adheres to the concept of "creating the future with intelligence, selecting excellence, integrating technology with intelligence, and leading the era". In the context of the globalization of new energy, we continuously provide customers with the best intelligent solutions and the most convenient services, helping the development of the global new energy industry and fulfilling the mission of green development!

- Solid state battery solution

- Lithium battery solution

- Sodium battery solution

- Other services

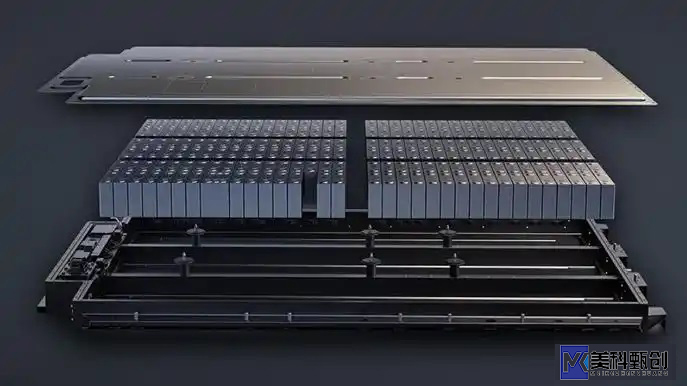

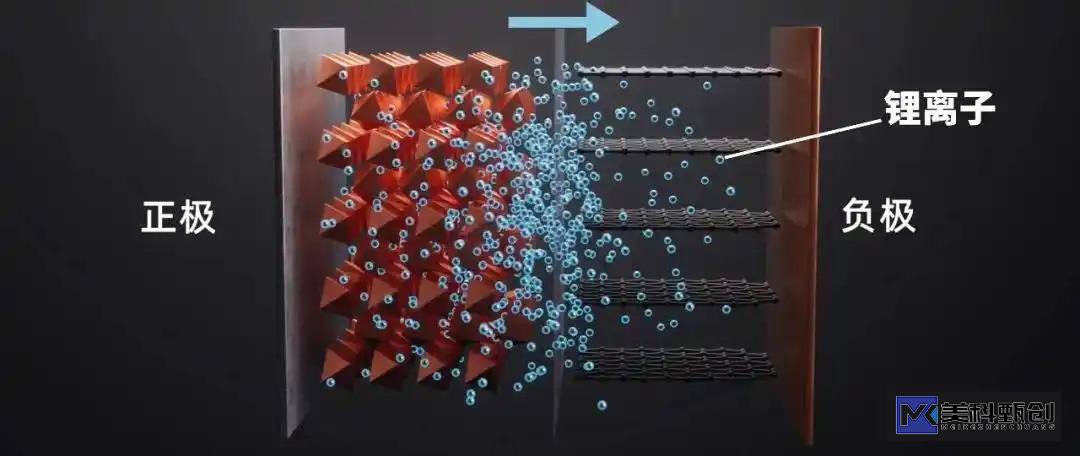

Meike Zhenchuang has integrated the manufacturing process of all solid state batteries and launched an all solid state whole line solution, covering key equipment for all solid state battery manufacturing such as all solid state electrode preparation, all solid state electrolyte membrane preparation and composite equipment, bare cell assembly to densification equipment, and high-voltage chemical capacity division. It has also completed the development of some high-speed mass production models.

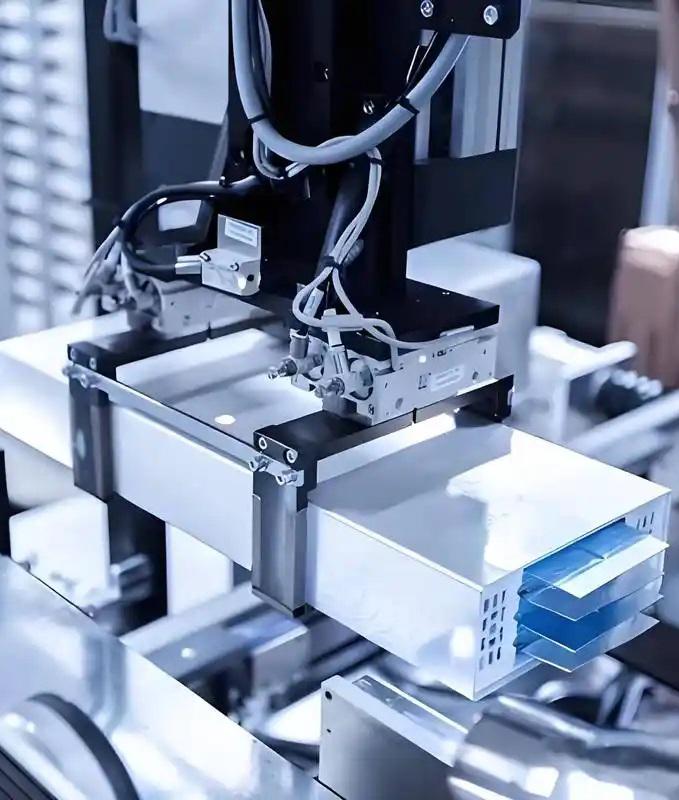

A lithium battery assembly line solution service provider with 100% complete independent intellectual property rights, with a core equipment market share of over 60%, committed to providing customers with lithium battery assembly line equipment from battery cell manufacturing, battery assembly, battery testing to module PACK and intelligent logistics systems, and equipped with a leading self-developed MES intelligent manufacturing system to create intelligent factories for customers.

Sodium battery assembly production line, complete the assembly of various components of the battery, automatic electrolyte filling and testing. During the production process, key parameters such as electrode quantity, thickness, electrolyte depth, and charging current are tested. The battery has a QR code, and the assembly process data is tracked and stored throughout the entire process.

Battery QR code printing 丨 Battery stack (electrode, current collector, diaphragm) 丨 Ear compaction 丨 Ear welding 丨 Ear shearing 丨 Dry battery charging test 丨 Battery cover loading and hot melt welding 丨 Electrolyte vacuum filling 丨 Battery pressure infiltration 丨 Electrolyte precipitation 丨 Wet battery weight detection 丨 Ultrasonic welding of detection holes 丨 Leakage testing 丨 Screw drilling of test holes 丨 Battery stacking 丨 Battery stacking compaction.

Supply of raw materials

Battery laboratory planning

Equipment supply

RECOMMENDED INFORMATION

Our Services

RECOMMENDED INFORMATION

Our ServicesPUBLIC WELFARE

Give back to society

PUBLIC WELFARE

Give back to societyMeike Zhenchuang closely follows the national "dual carbon" strategy, fully leverages the characteristics of its main business, and is committed to promoting the intelligent and green development of the entire industry chain. It implements the guiding principles of green, energy-saving, and environmental protection throughout the research and development process, and promotes the transformation and upgrading of green production and lifestyle in the whole society.