Complete Analysis of Battery Laboratory Construction: Creating an Industry Leading Research Platform

In the current booming development of the new energy industry, the importance of battery technology as a core driving force for research and innovation is becoming increasingly prominent. As a cradle for nurturing cutting-edge technologies and promoting industrial upgrading, the construction of battery laboratories in a scientific and efficient manner has become a focus of attention in the industry. This article, Nanjing Expansion Technology, will combine past cases of battery laboratory construction to deeply analyze the key links in battery laboratory construction, and present you with a comprehensive and professional construction guide.

1. Clearly define the construction goals and positioning

Before starting to build a battery laboratory, the primary task is to clarify its construction goals and positioning. This not only concerns the future research direction of the laboratory, but also determines its position and influence in the industry. For example, if the goal is to focus on the research and development of new battery materials, the laboratory's equipment configuration, talent reserves, and research strategies should all revolve around this core objective; If it is focused on the integration and optimization of battery systems, emphasis should be placed on capacity building in areas such as system testing and compatibility research. Clear goals and positioning are the cornerstone of battery laboratory construction, providing clear direction guidance for subsequent work.

2. Reasonable site selection and spatial planning

(1) Key points for site selection

The location of the battery laboratory needs to consider multiple factors comprehensively. Firstly, it is necessary to stay away from residential areas, traffic arteries, and noise sources to ensure a quiet and safe experimental environment. At the same time, it is necessary to consider the supporting infrastructure in the surrounding area, such as the stability of power supply and the completeness of the water supply and drainage system. In addition, geological conditions cannot be ignored, and it is necessary to avoid choosing areas with frequent earthquakes or unstable geology to prevent potential threats to the safety of experimental equipment and personnel.

(2) Principles of Spatial Planning

Clear functional zoning: The laboratory should be reasonably divided into different functional areas such as experimental area, office area, sample storage area, and waste disposal area. The experimental area can be further divided into cell preparation area, battery testing area, material analysis area, etc. Each area should be relatively independent to avoid mutual interference. For example, the battery cell preparation area has high requirements for environmental cleanliness and should be isolated from areas that are prone to dust generation; The battery testing area needs to consider issues such as equipment heat dissipation and noise, and layout the space reasonably.

Smooth flow of people and logistics channels: Design clear and reasonable flow of people and logistics channels to ensure efficient flow of personnel and materials. The pedestrian flow channel should be spacious and comfortable, meeting the requirements of emergency evacuation; The logistics channel should be reasonably planned for its width and load-bearing capacity based on factors such as the size and weight of experimental equipment and samples. At the same time, it is necessary to avoid the intersection of people and logistics, reduce pollution and safety hazards.

Reserved development space: Considering the rapid development of battery technology and the future business expansion needs of the laboratory, a certain amount of expandable space should be reserved in space planning. This can not only provide a place for the installation of new experimental equipment and research projects, but also adapt to the personnel expansion needs brought about by the expansion of laboratory scale, ensuring that the laboratory has good sustainable development capabilities.

3. Advanced equipment configuration and selection

(1) Core Equipment List

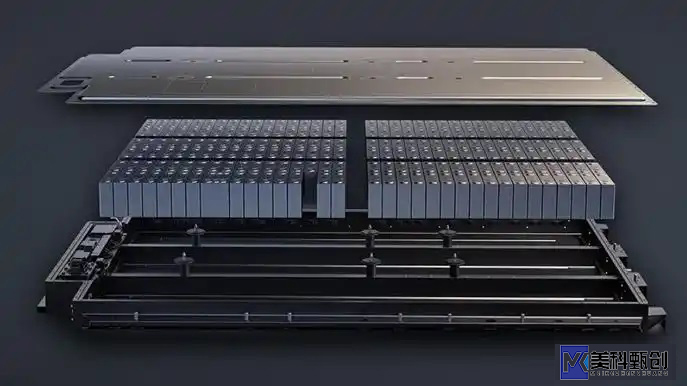

Battery manufacturing equipment: including mixers, coating machines, roller presses, laminating machines, winding machines, injection machines, etc. These devices are key tools for battery cell preparation, and their performance directly affects the quality and performance of the battery. For example, high-precision mixers can ensure uniform mixing of battery materials, thereby improving the consistency and stability of the battery; Advanced coating machines can achieve precise coating thickness control, laying the foundation for improving the energy density of batteries.

Battery testing equipment: including battery performance testers, charge and discharge testing systems, cycle life testing equipment, safety performance testing equipment, etc. The battery performance tester is used to measure basic parameters such as battery capacity, voltage, internal resistance, etc; The charging and discharging testing system can simulate the charging and discharging process of the battery under different working conditions, evaluate its charging and discharging efficiency and cycling performance; Safety performance testing equipment such as needle testing machines, extrusion testing machines, overcharge and over discharge testers, etc. are used to test the safety performance of batteries under extreme conditions, ensuring the safe use of batteries.

Material analysis equipment: including X-ray diffractometer (XRD), scanning electron microscope (SEM), Fourier transform infrared spectrometer (FT-IR), etc. These devices can be used for in-depth analysis of the structure, morphology, composition, etc. of battery materials, providing strong support for material research and optimization. For example, XRD can accurately determine the crystal structure and lattice parameters of materials, helping researchers understand the phase transition process and crystal defects of materials; SEM can visually observe the microstructure of materials, revealing their surface features and internal structure.

(2)Equipment selection principles

Excellent performance: Prioritize equipment with stable performance, high precision, and strong reliability. In the process of battery research and development, the accuracy of experimental data is crucial, so the equipment must have excellent measurement accuracy and repeatability to ensure the credibility of experimental results. For example, when selecting battery charging and discharging testing equipment, key indicators such as voltage, current measurement accuracy, and constant current and voltage control accuracy should be considered.

Compatibility and Scalability: Consider the compatibility between devices to ensure that different devices can work together and form a complete experimental testing system. At the same time, the equipment should have a certain degree of scalability and be able to meet future experimental needs by upgrading or adding modules. For example, some advanced material analysis equipment can achieve more functional expansion by adding different detectors or accessories.

Compliance with standard specifications: The selection of equipment should strictly follow relevant domestic and international standards and specifications, such as the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and Chinese National Standards (GB). This not only helps ensure the comparability and authority of experimental results, but also meets the requirements of product certification and market access. For example, equipment used for battery safety performance testing must comply with corresponding safety standards to ensure the safety of the testing process and the effectiveness of the test results.

4. Strict environmental control and protection

(1) Temperature and humidity control

Batteries are extremely sensitive to temperature and humidity, and even small environmental changes can have a significant impact on their performance and lifespan. Therefore, the battery laboratory must be equipped with a high-precision temperature and humidity control system. Combining with the battery laboratory project previously undertaken by Meike Zhenchuang, we will explain it to you. The project will accurately control the temperature within ± 0.5 ℃, and the dew point of the air in the battery laboratory is required to be below -60 ℃. This usually requires the use of a constant temperature and humidity air conditioning system, combined with temperature and humidity sensors for real-time monitoring and regulation, to ensure the stability of the experimental environment.

The construction of a battery laboratory is a complex and systematic project that requires comprehensive consideration and careful creation from multiple aspects, including clear construction goals, rational site selection and spatial planning, advanced equipment configuration, strict environmental control, professional formation of talent teams, and strengthening of quality control and safety management. Only in this way can a technologically advanced, functionally complete, safe and reliable battery laboratory be built, providing a solid support platform for the innovative development of battery technology and helping the new energy industry move towards a more brilliant future.